Say hello to carbon-neutral cooling and heating.

We build the most efficient heating, cooling and heat recovery systems.

ENERGY EFFICIENCY

Today. For tomorrow. Our energy systems reduce building energy costs and CO2 emissions by up to 85%.

HIGHEST PRECISION

Calculated to the finest measure. Ventilation systems with APESS® always provide optimum, customised solutions.

PERFORMANCE

Renovations or new buildings. APESS® calculates the most efficient configuration. Modular concepts allow real, affordable sustainability.

We are revolutionising air conditioning technology. Sustainably, with the aim of saving millions of tonnes of CO2.

APESS® GmbH

Air conditioning is our world. Maximum energy efficiency, high-precision system configurations and absolute safety are the cornerstones of our success.

APESS® GmbH combines years of experience, development work and competence in the fields of refrigeration and air conditioning technology, hydraulics and control engineering. With their environmentally friendly energy systems, energy centres can be planned and realised highly efficiently in existing as well as newly built properties.

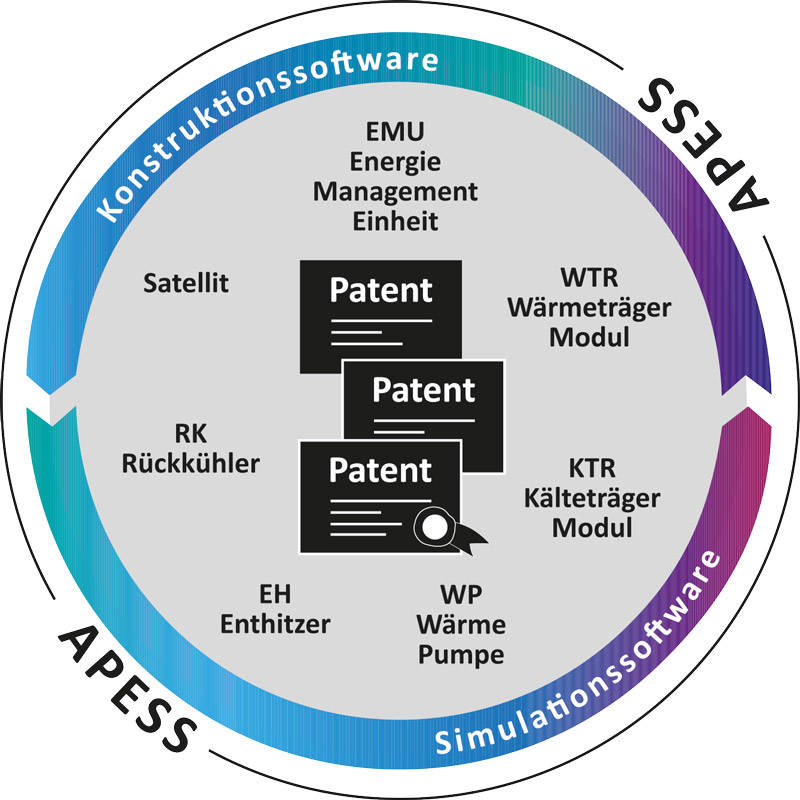

Behind the name APESS (Ambient Protecting Energy Saving Systems) are several process patents, individual modules and a unique software that allows the best configuration of the energy centre in each case and provides binding information on exact energy consumption and overall efficiency in advance.

Together with our partners, stakeholders and customers, we see enormous potential to save CO2 on a large scale, to make cooling and heating economical and to make an active contribution to achieving climate goals.

Together, we can change the world. And APESS® definitely has a role to play.

What we do: save energy, reduce costs. And much more.

Save resources and be sustainable.

- Reduce CO2 emissions by up to 85%

- Conserve resources with highly efficient heat pumps

- 100% independence from gas and oil

- Small amounts of refrigerant—longstanding compliance with the EU F-Gas Regulation No 517/2014

- Use of natural refrigerants (NH3, CO2, propane) possible

- Use of existing components possible

Wherever air needs to be conditioned.

- Fast, comprehensive system design with based on minimal information

- Carbon-neutral energy bills.

- Compatible with all ventilation units

- Low-noise operation

- Can be installed in historic buildings

- Perfect for new buildings and renovations which use existing components

- Fully transparent display

- Funding documents

- Comparisons with other systems possible

- Maximum support for planners from our team

Knowledge, experience and innovation. That’s what defines APESS®.

- Perfect configuration of system components and calculation of all thermodynamic processes as well as their optimisation in advance

- Brilliant logic: full use of exhaust air energy through two-stage heat recovery

- An overall control concept

- High compatibility with all heat recovery systems

- Subsequent installation in existing systems

- Integration of thermal solar photovoltaic systems, as well as geothermal probes and other energy sources (e.g. server rooms)

- Integration of other heat sources e.g. groundwater, waste heat from processes, sewerage, etc.

- Efficiency maximisation: free cooling; cold heat displacement; adiabatic exhaust air cooling; dehumidification cold recovery, etc.

- Constant or readjusted supply air temperature, even with variable air volume flows

- Stepless control

- High operational reliability

Cooling and heating do not have to cost the earth.

- Save on operating costs by up to 80%

- Short amortisation times—from as little as 6 months

- No CO2 compensation costs

- Costs for building conversions are often completely eliminated

- Existing components can be used in renovations

- Savings guarantee

- Funding

Questions?

Interested?

Call us or send us a message. We look forward to discussing how we can work together.

OPTIMAL ENERGY CONSUMPTION.

In office complexes, shopping centres, hospitals, hotels, swimming pools and all kinds of commercial and industrial buildings (e.g.: clean rooms, production facilities, etc.)

successful APESS® installations

of carbon emissions saved every year

"Saving energy is becoming more and more important for our customers, so with APESS® we got a solution portfolio that allows us to save maximum costs and CO2 in ventilation systems. We are just as excited about the results as our customers and see a lot of potential in APESS®!"

Rabmer GreenTech GmbH

Mag. Klaus Pichler

"In addition to our social responsibility as an internationally operating chemical company, we also want to be a role model in terms of environmental protection and sustainability in our region. With APESS® we have not only saved an enormous amount of energy and costs, but the investment costs have also paid off quickly."

CEO MERCK KGaA & Co Spittal

DI Klaus Raunegger, MBA

Not a new invention. And yet ingeniously innovative.

100% OPTIMISATION

APESS® is revolutionising building energy efficiency. With intelligent software and progressive components.

The calculation and optimisation of energy flows has accompanied us for many years. The logic of APESS® fully utilises the energy potential of the exhaust air and thus achieves a heat recovery of 100 %.

REFERENCES

We create a tailor-made solution for every challenge. Proven components, customised to your requirements. High efficiency always in mind. APESS® innovations are measurable.

APESS® innovations are measurable.

PlanNer?

Discover what APESS® can do and plan a green future with us!

Intelligent systems save time and create safety.

Our software presents complex solutions with maximum transparency and makes every project 100% traceable. The path to APESS® is simple: Only a few key data are necessary to receive a comprehensive system proposal including exact energy costs and CO2 emissions within a few days.

- High planning reliability

- Guaranteed to be the most efficient solution

- Enormous time saving

- Permanent support in the planning and implementation process

Survey phase

Transmission of the technical design data of the full air-conditioning units, heating and cooling load as well as the design schemes

Design planning

Developing a design plan with the help of the APESS® software, which at the same time also indicates the energy consumption and savings potential that can be expected upon realisation.

Optimisation phase

Improvements or consideration of special customer requirements such as the use of natural refrigerants or free cooling and simulation of the optimised system.

Tendering phase

The planner receives all documents, including calculated data, HX diagrams and information, in order to be able to make the tender. All documents for funding applications are also included here.